Applications PAGE 13

Laser Applications

Our Laser System Applications

There are an innumerable number of applications for industrial lasers. Lasers are used for welding, cutting, marking & engraving, cleaning, and rust removal. There are a variety of types of laser sources, wavelengths, and laser powers, from a 5W UV marking laser up to a 40kW fiber cutting laser. The differing types provide differing capabilities and materials to work with. Most lasers will work with many metals, and certain lasers, such as MOPA, have wider ranges of materials than other more specialized lasers, such as a UV laser, but each type suits particular applications.

Industries We Serve:

Types of Laser Systems

Lasers are used for many industrial applications. Laser Americas provides systems for Laser Welding, Cutting, Marking, Etching and engraving, and Rust Removal and cleaning.

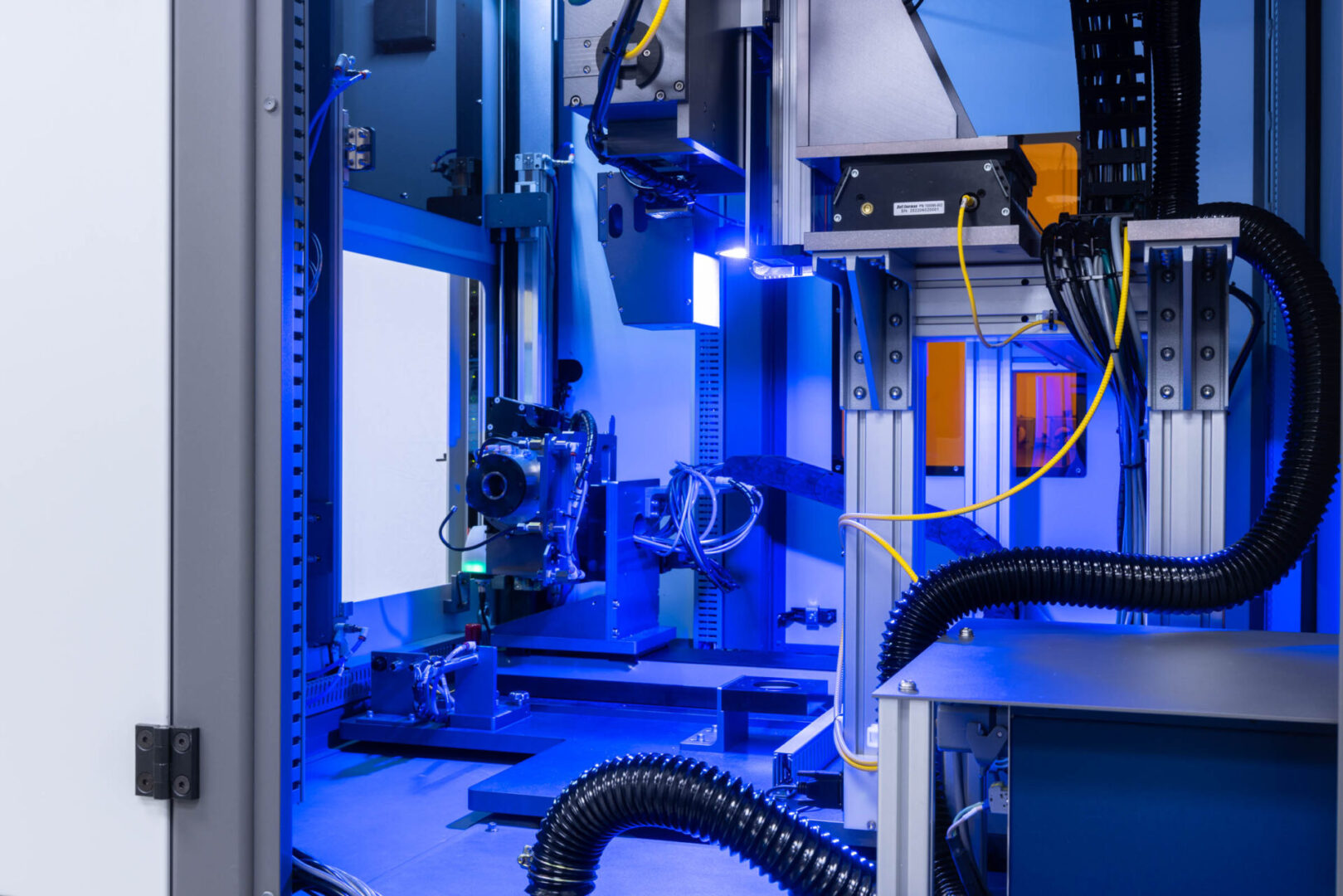

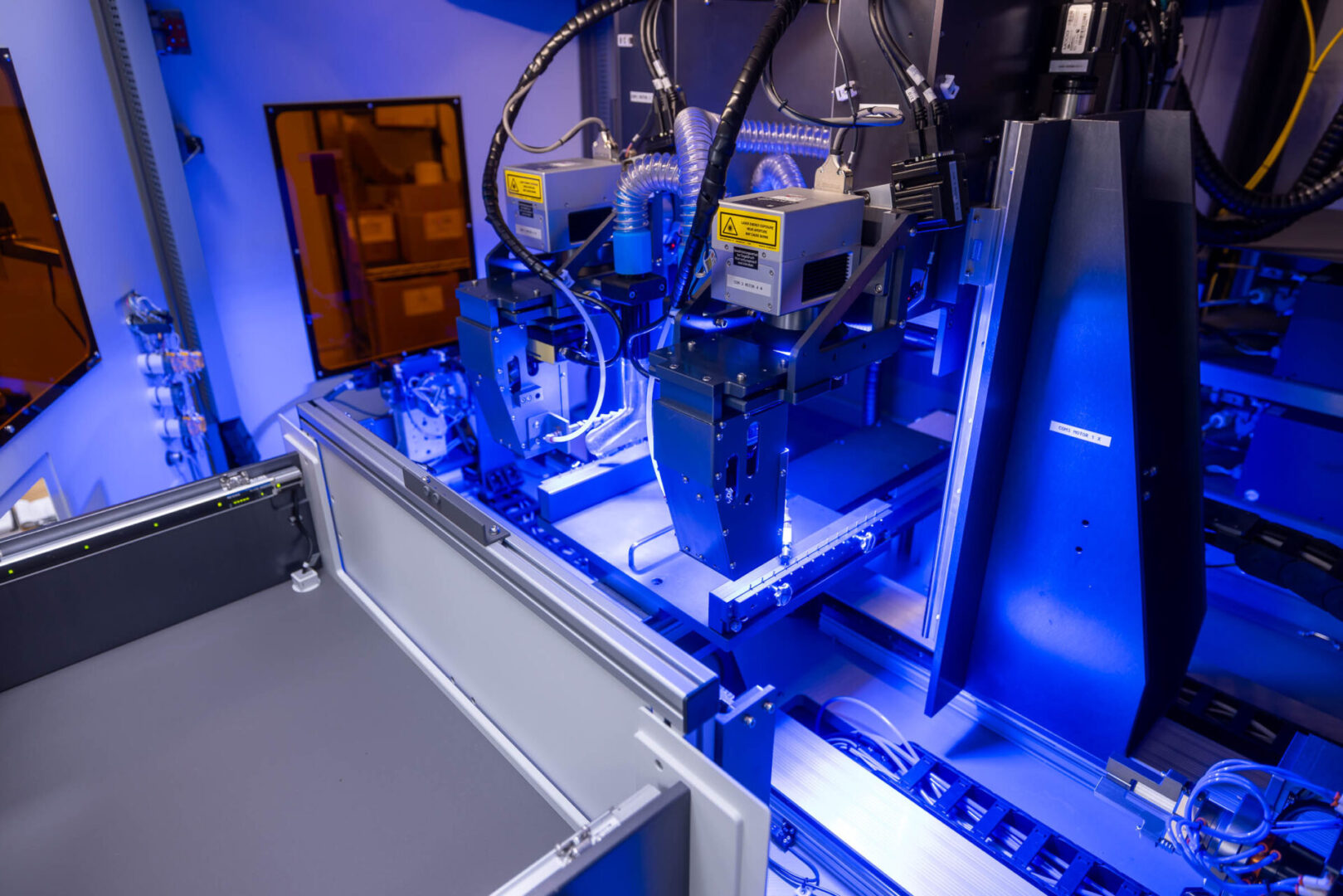

Laser Welding

Laser welding provides high-integrity welds on similar and dissimilar metals. Capable of welding aluminum, steel, stainless steel, titanium, and other ferrous and non-ferrous metals up to depths of 0.150” deep. Laser Americas’ welding systems are available in either Class I (no goggles required) or Class IV (goggles and shielding required). Enclosed systems (Class I) can include advanced automation and material handling, and even some Class IV portable systems can have material handling integrated.

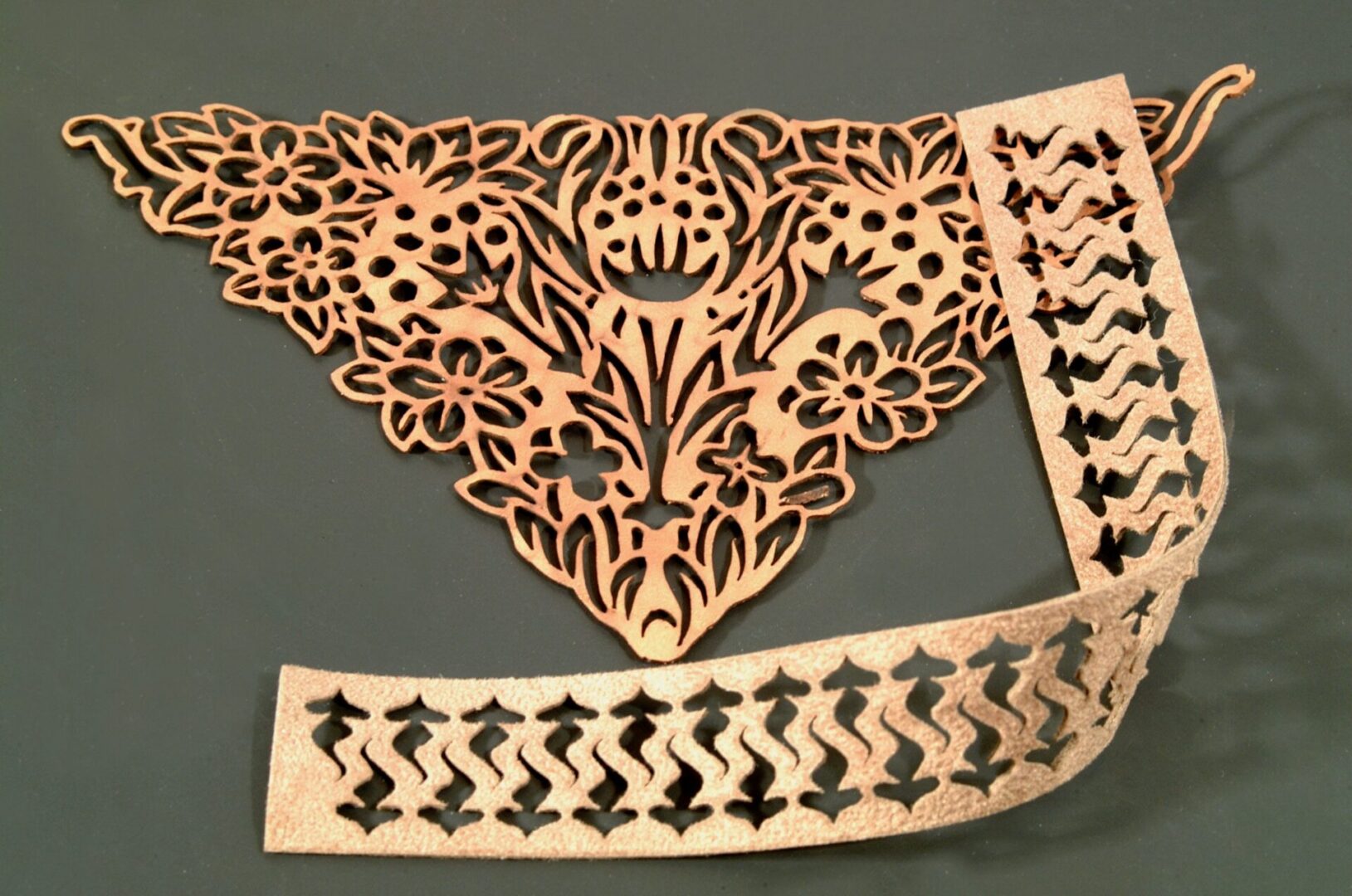

Laser Cutting

Laser Cutting relies primarily on two differing laser technologies. The first is CO2, which is an older laser technology that performs very well to this day. CO2 lasers are primarily used for organic materials, e.g., plastics, wood, fibers, etc. CO2 lasers can also be used for engraving organics and marble & granite. CO2 lasers typically max out in their power levels at under 1000 Watts. The other type of laser used in cutting is a fiber laser, which operates at a considerably shorter optical wavelength and is primarily used for cutting metals. Fiber lasers can be extremely powerful at up to around 40 kilowatts and are capable of cutting through 1”+ thick steel.

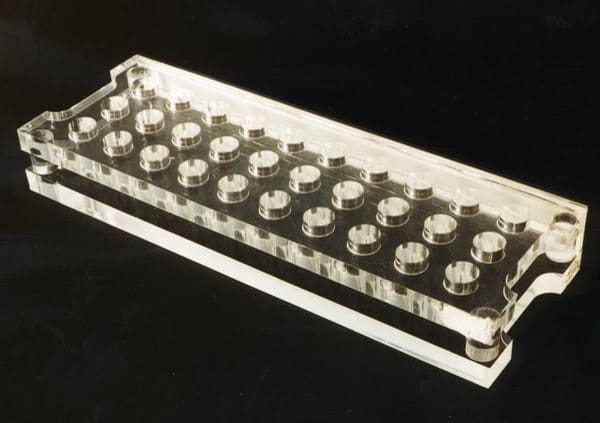

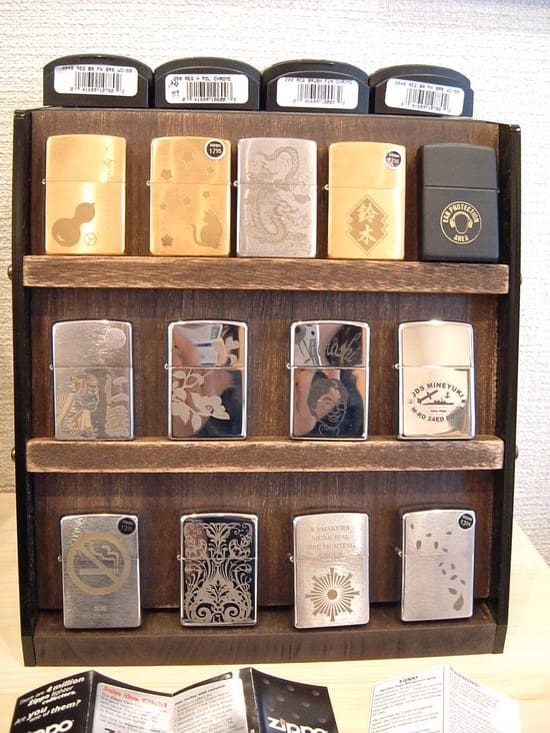

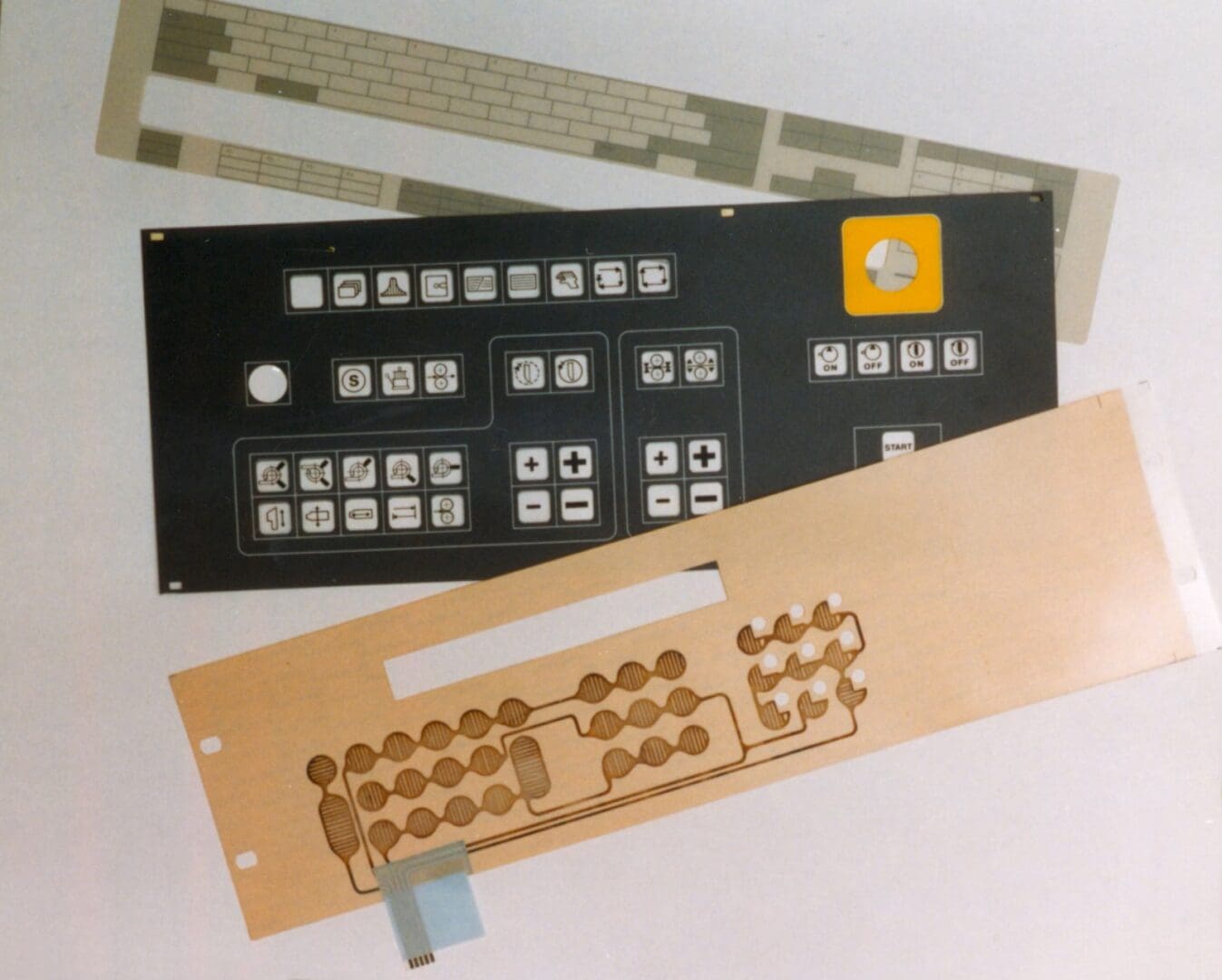

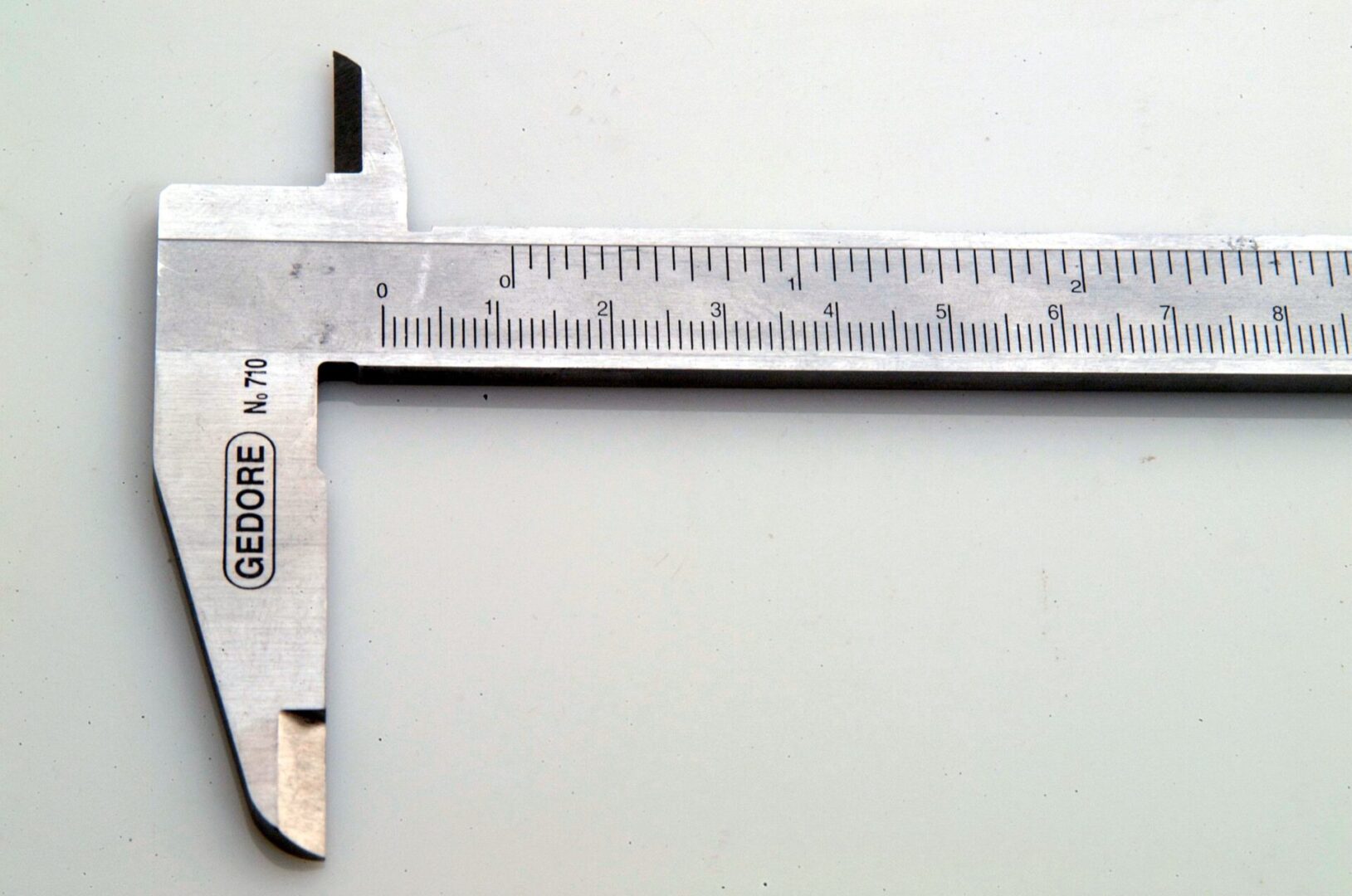

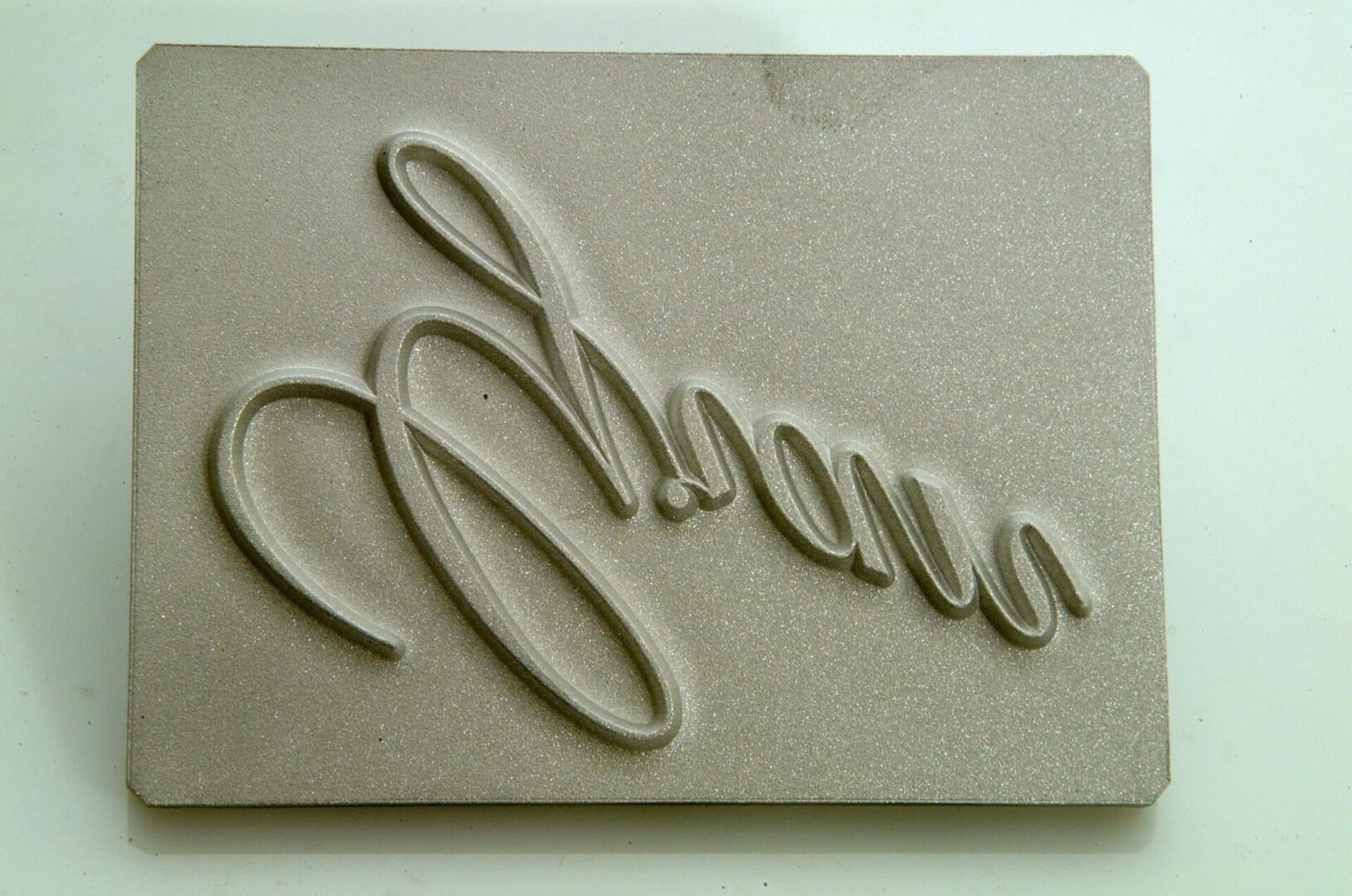

Laser Marking & Engraving

Lasers are extremely useful in providing permanent marking and engraving on almost any material. Differing technologies are optimum for different materials and intended uses. There are seven different technologies currently available: CO2, Fiber, MOPA, Green, Pico, Femto A& UV. Each has specific benefits and uses: CO2, like the cutting, is primarily for organics, Fiber is primarily for metals, MOPA is for both metals and SOME plastics, Green lasers are mostly for marking sensitive materials and precious metals, Pico lasers are excellent for providing permanent black marks on stainless such as in medical instruments, Femto lasers are ideal for micromachining, and UV lasers are primarily for use on organics. As in the diversity in technologies, there is a considerable range of pricing for the various technologies. Laser Americas has the experience to connect a user with the optimum technology, both cost and efficiency-wise.

Laser Rust Removal & Cleaning

A relatively new application for lasers is for laser rust removal and surface cleaning. Laser Americas also has a variety of systems to choose from. Laser rust removal and cleaning have significant advantages over sandblasting and sanding as they will not remove the derlying material, unlike those other two techniques.