Learn More PAGE 3

Learn More from Laser Americas

Our Laser System Capabilities and Applications

Who We Are:

The Laser Americas Team has been continuously involved in the laser industry for over 30 years. We didn’t start out in a related industry and end up in the laser business through acquisition or evolution ‒ we were born and raised in the lasers.

We started out providing laser configuration and integration solutions for an impressive list of industrial clients. We developed the custom applications that these companies required to reach their specific production needs. With each new customer came a new challenge, a different material, and a unique requirement. We made our bones solving these challenges and building an impressive knowledge base as laser technology evolved.

It wasn’t long before customers started turning to us for support and service. In many cases, we’ve done development work to help create a final product that presented difficult technical challenges. We strive to make working with Laser Americas a positive and collaborative experience. We know what it’s like being under the gun and will work non-stop to meet your deadlines and design criteria.

Why not give us a call and talk to us about your laser system needs? We’re quite sure you’ll be glad you did.

To stay up to date about Laser Americas, click below for our News Releases and White Papers:

Industries We Serve:

Industrial lasers have revolutionized manufacturing processes across various industries. The precise and controlled energy output of lasers has enabled a wide range of applications, including laser welding, cutting, marking, and engraving, as well as laser rust removal and cleaning. The various systems that Laser Americas offers are:

1. Laser Welding:

Industrial lasers, such as CO2 and fiber lasers, offer exceptional precision for welding applications. The focused laser beam generates intense heat, allowing for precise control and minimal material distortion. Laser welding finds applications in automotive, aerospace, electronic, and medical device industries, providing high-quality joint completion and increased productivity.

2. Laser Cutting:

Laser cutting is a versatile process used across industries to cut various materials like metals, composites, and plastics precisely. CO2 and fiber lasers are commonly employed for cutting applications. The focused laser beam melts or vaporizes the material, producing clean and accurate cuts with tight tolerances. Laser cutting allows for complex shapes, intricate patterns, and high-speed production.

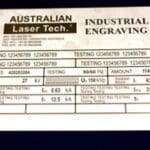

3. Laser Marking and Engraving:

Laser marking and engraving use lasers to create permanent and precise marks on a wide array of materials, including metals, plastics, glass, and ceramics. CO2, fiber, UV (ultraviolet), and green lasers are suitable for marking and engraving applications. The laser beam removes or modifies the surface material, achieving durable, high-resolution marks, barcodes, logos, and serial numbers. This process finds utility in industries such as jewelry, electronics, aerospace, and automotive.

4. Laser Rust Removal and Cleaning:

Industrial lasers, including CO2 and fiber lasers, are effective for rust removal and cleaning applications. The laser energy ablates or vaporizes rust, paint, or contaminants without damaging the underlying substrate. This non-contact and environmentally friendly process offers precise cleaning of intricate surfaces, such as delicate machinery or historical artifacts. Laser cleaning is increasingly used in the automotive, aerospace, and maintenance industries.

Types of Lasers:

Finally:

From powerful laser welding and cutting to precise marking, engraving, and rust removal, industrial lasers offer a wide range of applications in numerous industries. CO2, fiber, MOPA, UV, green, pico, and femto lasers each bring unique capabilities to meet specific industrial needs efficiently. As technology advances, the potential for industrial laser applications continues to expand, offering increased efficiency,